Welcome to the website of Artbri Technology Limited !

Artbri Technology Limited

Focus on the development of sophisticated, digital and intelligent battery test equipment

Consulting Hotline (Mr. Liu):

+86 173-2848-0575

- home

-

Resistance test equipments

- Four probe resistance tester

- Four probe high resistance tester FTZ-45

- Four probe double electric resistance tester FTZ-42S

- Four-probe double electric resistance tester FTZ-45S

- Four probe double electric thickness resistance tester FTZ-42ST

- Four-probe double electric thickness and high resistance tester FTZ-45ST

- Soft pack battery voltage internal resistance tester SB-15

- Cylindrical battery voltage internal resistance testing machine YZ-20

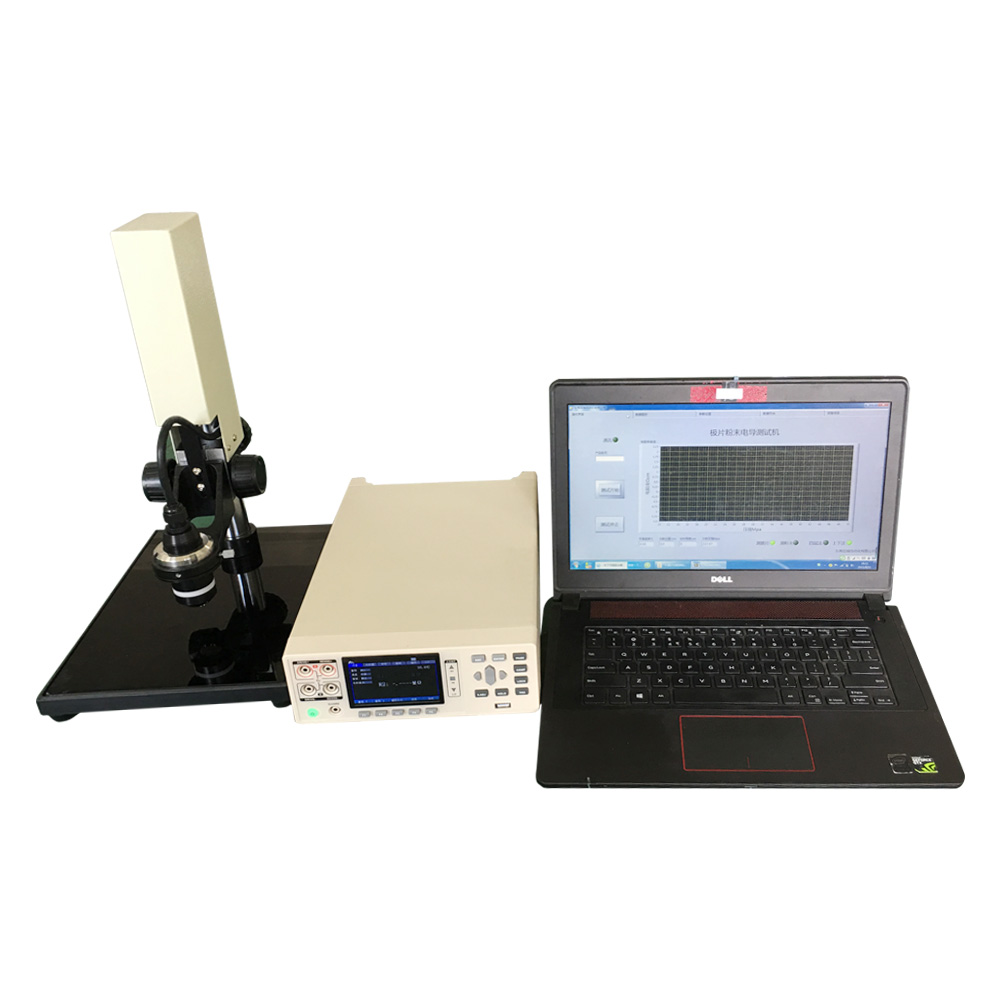

- Separator ion conductivity Tester

- Electrolyte high and low temperature saturated steamPressure & Conductivity conductivity tester

- Separator Shutdown & Break Tester closed cell rupture test machine ART-GMT-35L

- 5 ton Sheet & Powder resistance compaction density tester

- 1 tonSheet & Powder resistance compaction density tester

- Automatic Sheet resistance tester FTZ-45A

- Sheet Resistance Tester

-

Products

-

Temperature-controlled Altitude Simulation TesterTemperature-controlled low-pressure high-altitude testing machineBattery pack short circuit testing machinePurification fume hoodTemperature-controlled power battery short-circuit testing machineBattery explosion-proof boxPower battery automatic fire extinguishing and explosion-proof boxBattery thermal runaway gas production testerAutomatic fire extinguishing fume hoodCylindrical battery leakage and burst testing machineimpact testing machineBattery pack Seawater immersion test machineBattery pack fire test machineThree-box thermal shock testing machineThree-box temperature-controlled short-circuit testing machine100 ton temperature control servoCrush & Penetration punch testing machine

- Battery performance test equipments

- Lithium battery production equipments

- Custmized Automation equipments

- Tooling & Spare Parts for Battery Equipments

-

Temperature-controlled Altitude Simulation Tester

- Video Center

- News

- about us

- contact us